Fighting Corona Together!

Starting in April, SIGMA Engineering, Arburg and many other partners joint forces to work on a new project against the spread of the coronavirus.

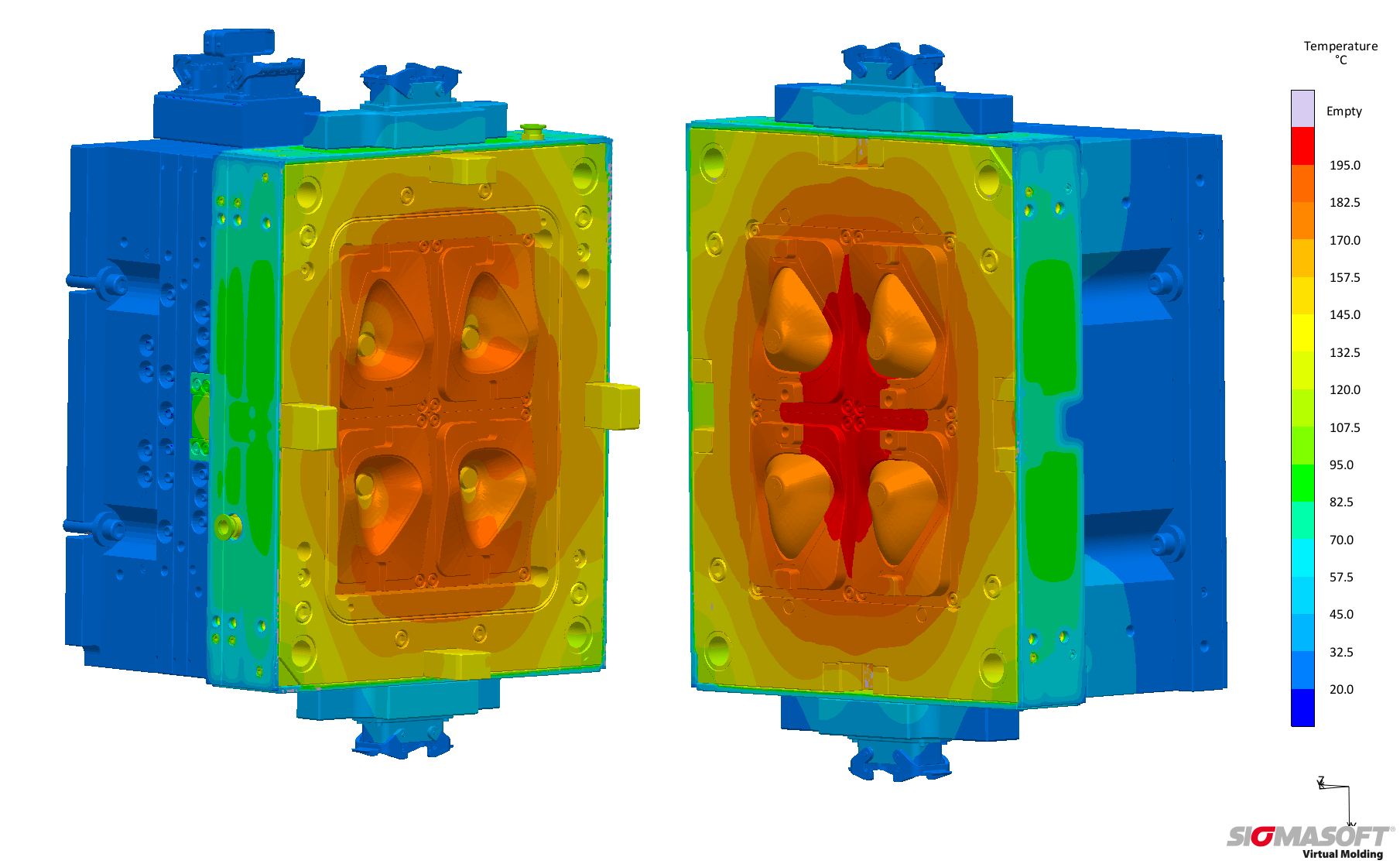

Now the production of injection molded masks made of LSR (Liquid Silicone Rubber) is running at full speed. SIGMASOFT® Virtual Molding was used to determine and optimize injection points, pressure requirements, temperature distribution, air entrapment, and the crosslinking of the LSR material.

"We noticed a high demand for protective masks from the public as well as from our own employees, which made this project-cooperation highly welcome. Due to the successful and focused cooperation with partners such as Arburg and Polar-Form we were able to simulate the layout of the complete LSR mold within shortest time and optimized the mold design for process-efficiency and robustness". Thomas Klein, CEO SIGMA Engineering GmbH

More Than Just a Feasibility Study

For a smooth production of the masks, Tobias Sonntag, project engineer at SIGMA, used SIGMASOFT® Virtual Molding to evaluate the position of the injection point, the venting system, and the thermal design even before the mold was cut. The prediction of the process parameters and required curing time was also an important result of the simulation.

"We examined a lot of different factors. But the focus was on component quality, optical properties and, of course, the safety of the user that comes with a perfect component free of air entrapments or other defects. But also, a fast and resource-saving process design was very important to us," says Sonntag about the requirements for the project and part.

Energy-Efficient and Resource-Saving Through Simulation

There is no need to guess how the mold reaches its thermal steady state. Since SIGMASOFT® Virtual Molding will precisely calculate the required number of cycles - the reliability of mass-production is secured. For an exact control of the temperature distribution, the number of temperature sensors in the mold was increased to six and their positions were optimized based on the simulation results. This allowed a focused regulation of the heating cartridges. In addition, an optimal insulation of the mold reduced the required energy to a minimum - energy waste was avoided.

SIGMA completed the project within 24 hours, from the mold setup to the filling calculations and the thermal layout. A total of four parts per cycle are injection molded at 180 °C from the non-postcure LSR Elastosil LR 5040 supplied by Wacker. The required symmetrical temperature pattern of the four cavities was first created and optimized in a simulation using optimal insulation, six temperature sensors and regulatable heating cartridges, and then realized by Polar-Form in the mold construction.

"To design a mold under pressure without component and process references is the strength of SIGMASOFT® Virtual Molding" summarizes Thomas Klein. "The partners were under enormous pressure because everything had to run smoothly right away. We are highly pleased that the mold ran in the computer first and mistakes were avoided. This way, an efficient process was created very swiftly. Thanks to all partners for the joint success."