The new Precision!

In the elastomer industry, you face multiple daily challenges directly affecting the productivity of your mold:

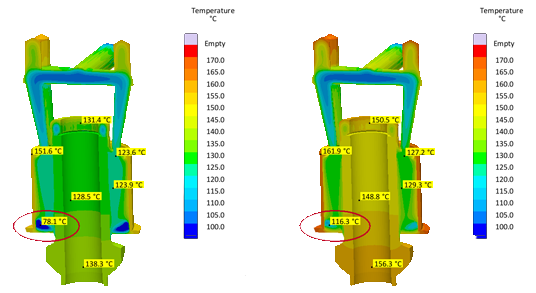

- Positioning, number, and power of the heating cartridges

- Optimization of heating time and detection of cold spots

- Effectiveness of insulation between cold runner and hot mold

- Temperature sensor positioning

- Precise and energy-efficient production

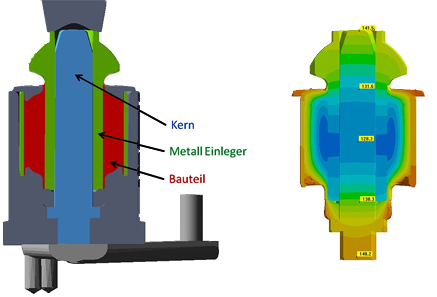

Using the Virtual Molding technology, you can establish the same process conditions as on your real machine and run several production cycles virtually one after the other. Accurately simulate curing, process times, and inserts of all kinds. Get to know your mold very precisely and optimize your mold design and performance in detail.

SIGMASOFT® VIRTUAL MOLDING SUPPORTS SOLVING COMPLEX CHALLENGES IN INJECTION MOLDING FROM DESIGN TO PROCESSING.

WHAT YOU CAN EXPECT FROM SIGMASOFT®elastomer:

- Predict cavity filling, flow front distribution, fountain flow, block-shear flow, and jetting effects

- Cold runner calculations

- Simulate cascade and multi-component injection molding

- Simulate tempering processes and low viscosity elastomers

- Predict shear gradients

- Simulate clamping force and holding phase (packing pressure phase)

- curing stage and scorch during filling results

- Consider curing degree dependent viscosity as well as exothermic curing reaction and its influence

- Calculate curing time, curing stage, and post-curing outside the mold

VIRTUAL MOLDING INSTEAD OF JUST SIMULATION: THE MOLD MAKES THE DIFFERENCE!

Not only the behavior of the part but also the thermal behavior of the mold can be analyzed and optimized with SIGMASOFT®elastomer. You will accelerate the development process and achieve the desired part quality from the very first shot. Furthermore, you are able to start the virtual series production even before your mold is built.

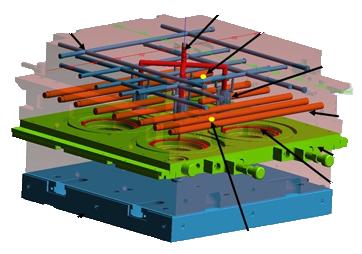

Intelligent, automatic meshing algorithms allow you to mesh an entire mold in less than five minutes. Mesh repair, triangle offsets, or taking away rounding or chamfers belong to the past. Take a look inside the mold while it is running.

MAKE SIGMASOFT® YOUR TOOL AND...

... YOU WILL GET MORE OUT OF YOUR PROJECTS!

OUR IN-HOUSE DEVELOPMENT AND the TEAM OF HIGHLY QUALIFIED ENGINEERS IS THE SERVICE WE PROVIDE TO YOU!

Successful injection molding simulation requires the direct contact between the users and a competent engineering team. Therefore, our solution service, our customer support as well as our application-oriented software developers work closely together with you for your success!

SIGMASOFT®

elastomer INFORMATION FOR YOU TO DOWNLOAD!

YOUR INSIGHT INTO OUR CASES STUDIES:

Casestudy

ELASTOMER TROUBLESHOOTING:

THE INFLUENCE OF INSERT PREHEATING

Casestudy

HOW RELEVANT IS TIME IN INJECTION MOLDING?

Casestudy

THERMAL ANALYSIS DELIVERS FIRST-SHOT-SUCCESS IN RUBBER INJECTION MOLDING