SIGMAinteract® EXAMPLES

The Updated INTERACT is here!

Dynamic background loading allows you to work even faster with the SIGMAinteract. The display of clip planes is improved - for an even better look into the inside.

Optimized presentation of shrinkage results: The change in comparison to the original part geometry is clearly visible - the shrinkage scale is continuously adjustable with a slider. The original geometry can be shown or hidden with only one click.

The "fit" button allows you to align the part geometry to fit the SIGMAinteract screen - without any effort.

Simply test it yourself with our examples:

360 Degrees and fully filled

With the Interact the mold fillings individual result can be checked in 3D from any angle.

Tracer particles and flow front

View the materials flow front in detail and always know exactly how the material fills the component at different flow rates.

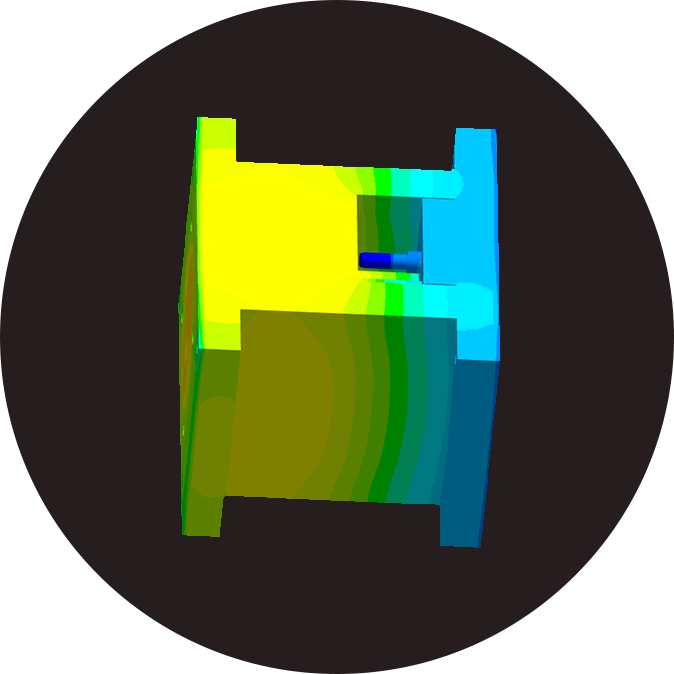

The view into the mold

The entire temperature distribution becomes visible as the Interact shows the molds interior.

Pressure distribution in the component

Observe step by step whether the component is filled with the correct filling pressure.